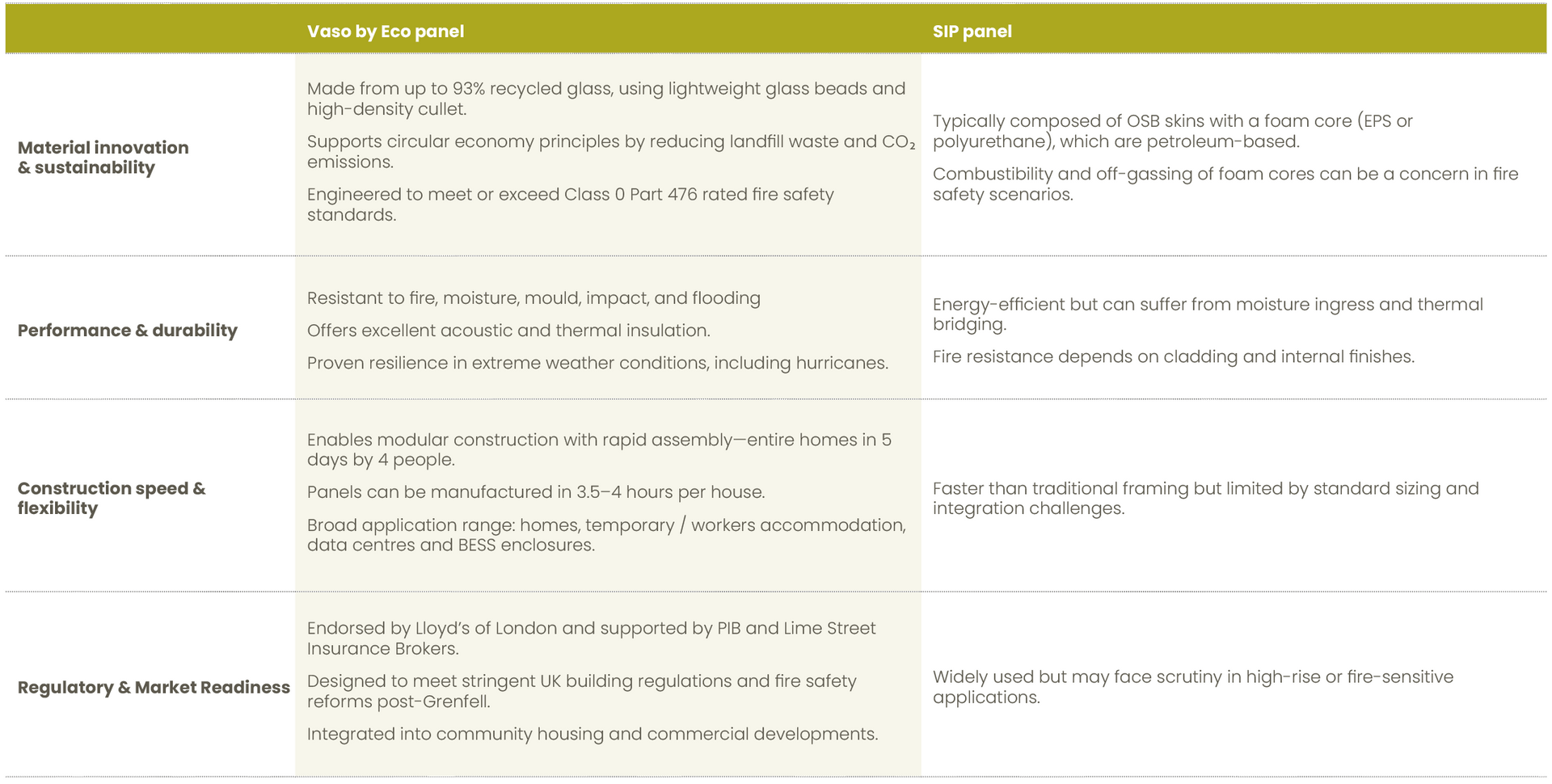

About our product.

Like a SIP panel,

But better.

.

Our structural composite panels made from recycled glass helps the built environment deliver structures rapidly, responsibly and sustainably by precision manufacturing and innovative technology unlike anything else.

This composite panel interweaves embodied carbon reduction for generations with advanced material construction that avoids traditional supply chain market fluctuations. Engineered for fast-track build deployment and resilience to extreme weather conditions, it drives progress in construction sustainability, performance, and affordability.

our buildings are:

affordable

Capital costs akin to traditional construction, can be specified as 'Energy Positive' buildings.

design in mind

Flexible floor plans for all budgets. Designed to replicate traditional build styles and practicality.

technological advantages

SIP panel points of failure

Moisture Management

- Condensation & Water Infiltration

- Waterproofing Challenges

Thermal Bridging

Insulation Quality

Fire Safety Concerns

- Flammability

- Code Compliance

Pest Infestation

- Vulnerability to Pests

- Preventative Measures

Structural Integrity

- Load-bearing limitations

- Panel damage

Installation Challenges

- Skilled labour requirements

- Precision in assembly

Cost Considerations

- Initial costs

- Repair & maintenance

Design Flexibility

- Design limitations

- Integration with other systems

Composite skin

The composite skin we bond to our panel can be formulated to achieve performance such as:

- Ballistic specification against projectile and armaments

- Anti-microbial, where the skin kills bacteria and virus on contact

- RF Shielding, for use in telecommunications and military

- Lead lining for CT and MRI shielding

- Clean room applications such as bio-medical and electronic assembly

- Washdown areas such as abattoirs, food processing and chemical

EPC methodology underestimates the performance of monolithic composite structures because it was designed around failure mechanisms that composites simply do not have.

product opportunity

Testing:

Extensive design and testing ensures that no matter the requirements, the build system has the flexibility to perform to any design brief.

Resistant to:

- Fire - Class 0 Rating

- Impact - Category 5 Hurricane Projectile Resistance

- Flooding - Ideal for Flood Proof Housing Schemes

- Structural Issues - Meets the most demanding of criteria

Corrosion:

Buildings situated near the coastline are at high risk from the effect of saltwater corrosion, leading to costly maintenance and deteriorating structural performance.

As part of the Build System, our composite materials and completely unaffected by this factor, aswell as superior structural assistance to extreme forces such as earthquake, hurricane, tidal wave and tsunami.

Thermal efficiency:

Test carried out by University of Manitoba, Canada.

Survey conditions:

- The ambient temperature outside at the time of survey was - 20°C, with the interior temperature at approximately 20°C. The wind speed was noted at 7km/h at the time of the survey.

Observation:

- The general condition of the building was excellent with no appreciable heat loss noted. The structure was found to be extremely efficient blocking the transfer of heat/cold.

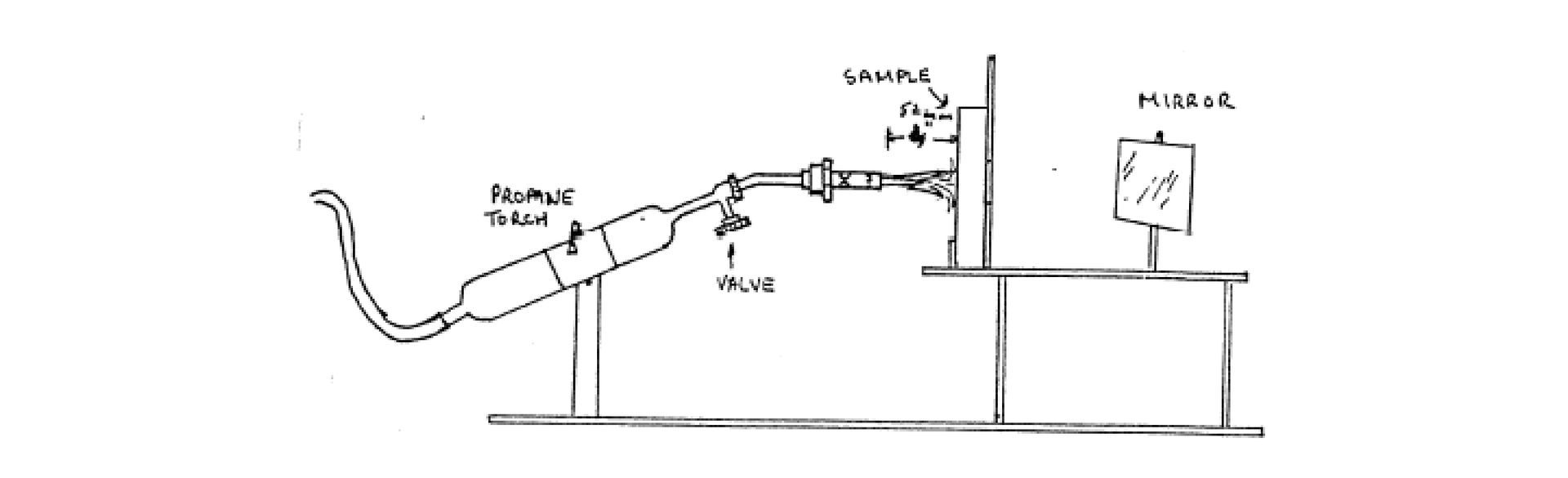

Burn through tests:

Survey conditions:

- Indicative test

- The propane burning is tested to check whether it reached 1000°C

Material Performance in Cold Weather

- Concrete: Should not be poured below 5°C unless special precautions (like heated enclosures or additives) are taken. Below this, curing slows significantly and can compromise strength.

- Mortar: Similar to concrete, mortar should not be used below 4°C without additives or protection.

- Adhesives and sealants: Many have minimum application temperatures around 5–10°C

- The Vaso by Eco panel outperforms existing build materials