About Vbar.

Like steel rebar,

but better - Vbar.

.

Leading the way to decarbonising reinforced concrete. Soaring steel prices, environmental awareness and aging infrastructure has highlighted the need for a better, higher performing material to that of steel. The construction industry is now asking for a solution.

Composite rebar in concrete is widely used in the USA and the Americas and has proven to be superior to that of traditional steel reinforcement. Composite rebar has 100+ years of service life. It is made to reinforce concrete and engineered to stay that way for centuries. It is an effective way to extend the service life of any project. With proper design and planning at the start of projects, using composite rebar reduces costs and expenses in the long run.

GRRP is made to withstand a 20x higher resistance than steel rebar with other qualities such as increased fatigue and high chemical resistance. It is also highly resistant to alkaline environments and chemicals, such as de-icing salts. It is a material that can deliver high performance even in freeze-thaw climates, excellent for use in coastal areas and cold temperatures.

Not only are the merits of the performances over steel a consideration, so is price and handling costs. Lower freight costs, lighter to handle and more resistant to damage and bending during distribution are just some of the many advantages and economies.

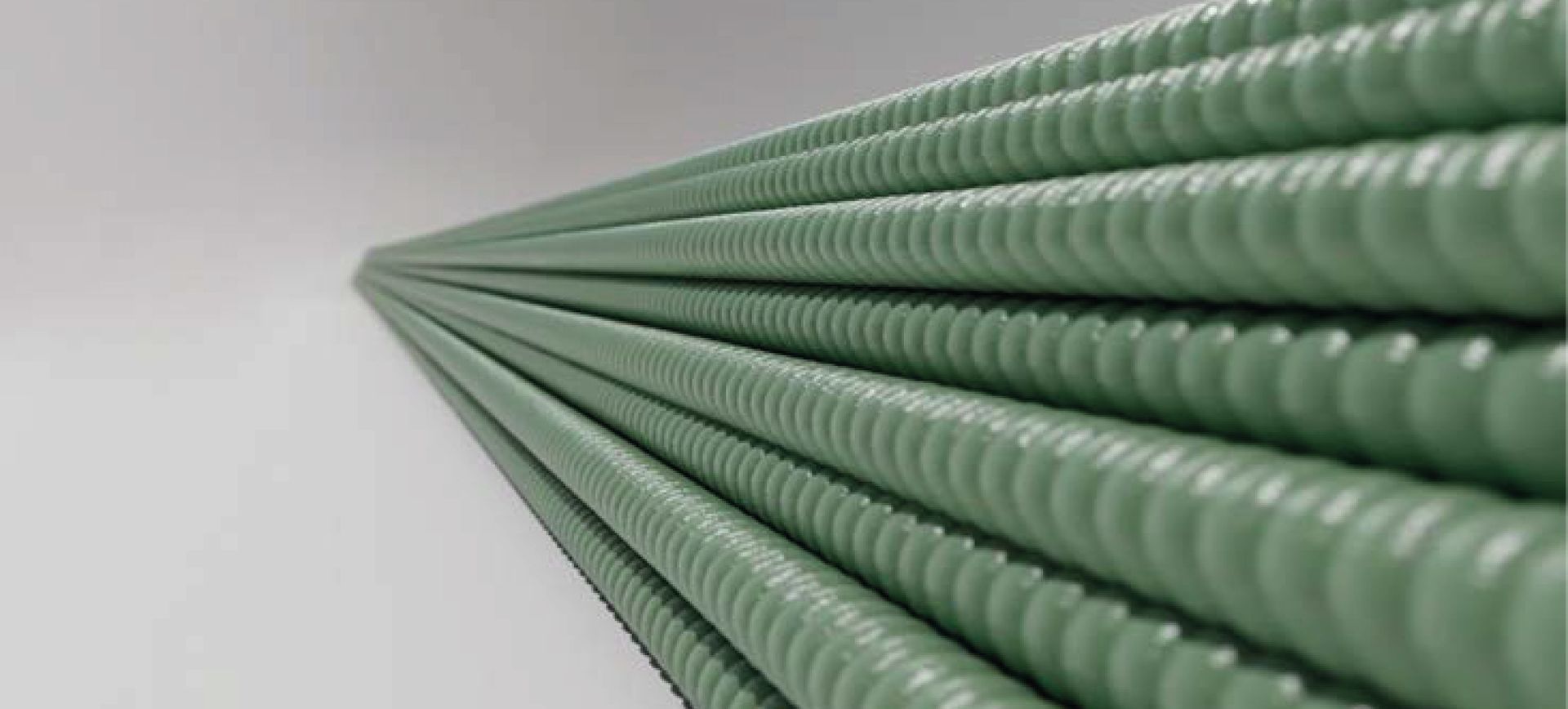

Vbar is non-corrosive and suited to any environmental exposure. Does not conduct heat, cold, or electricity and is available in all straight and mesh sizes.

benefits of Vbar:

lifespan of 100+ years

Vbar is designed to never corrode, which helps prevent spalling in concrete. With a lifespan of over 100 years, MST-BAR® outlasts the concrete it reinforces.

Vbar solution

Steel rebar corrosion

100 years ago, steel rebar was developed as the only option for reinforcing concrete. However, many of the structures developed before steel rebar are still standing today.

Structures using steel rebar in corrosive environments will begin to fail after 10 years. Corrosion costs the private and public sectors hundreds of billions of pounds in repair and maintenance costs a year. Corroding steel rebar is a ticking time bomb because determining the moment of failure can mean the difference between life and death.

Our Vbar can save the current costs of corrosion and eliminate all failures due to corrosion because it will outlive the concrete it is reinforcing.

Vbar solution

Straight bar

- Structural and non-structural rebar

- Available in custom lengths

- Standard lengths 3m & 6m

- Diameters in stock: 10mm - 25mm

- Custom diameter up to 55mm

Bent bar

- Structural bent rebar

- Custom shapes for any project

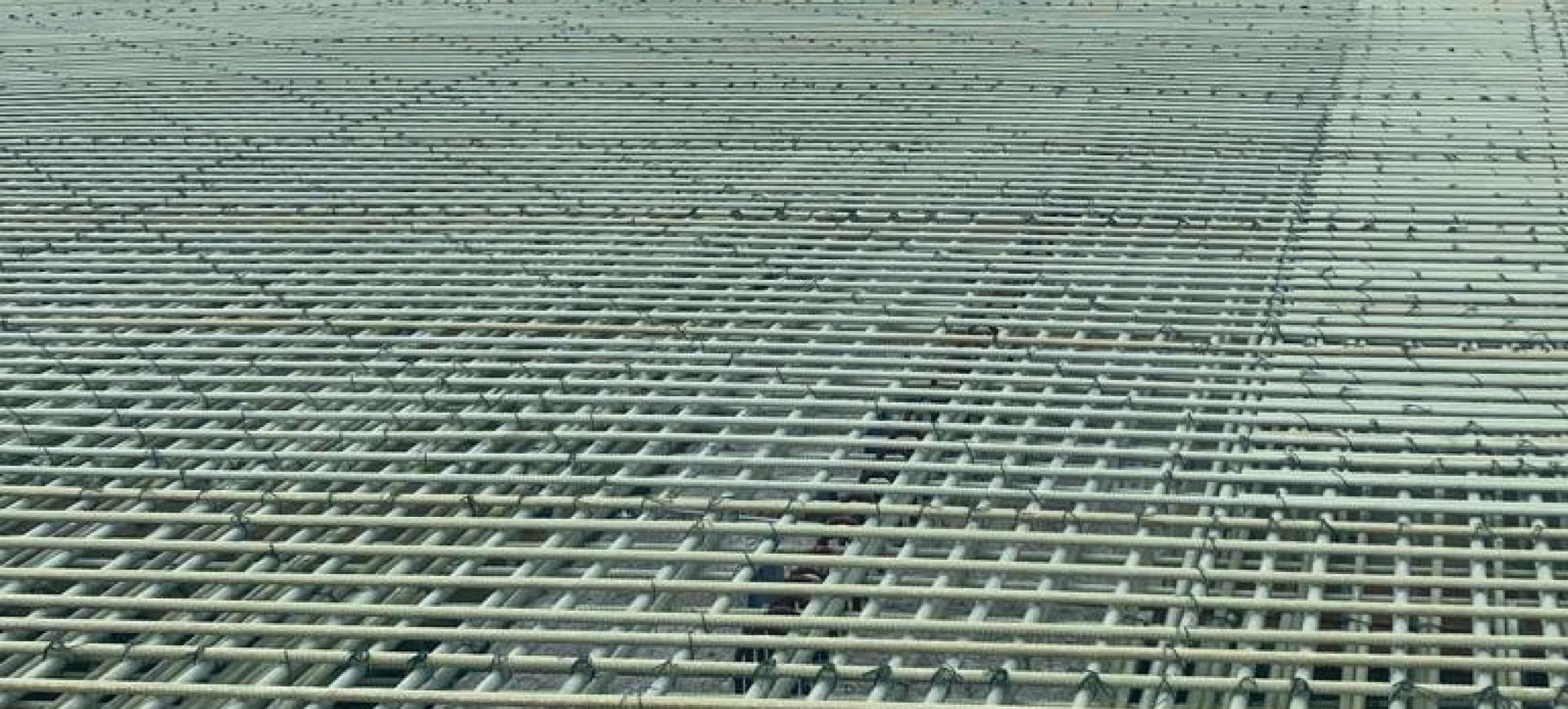

Mesh bar

- Available in most UK standard sizes including A, B, C & D British Standards Reference.

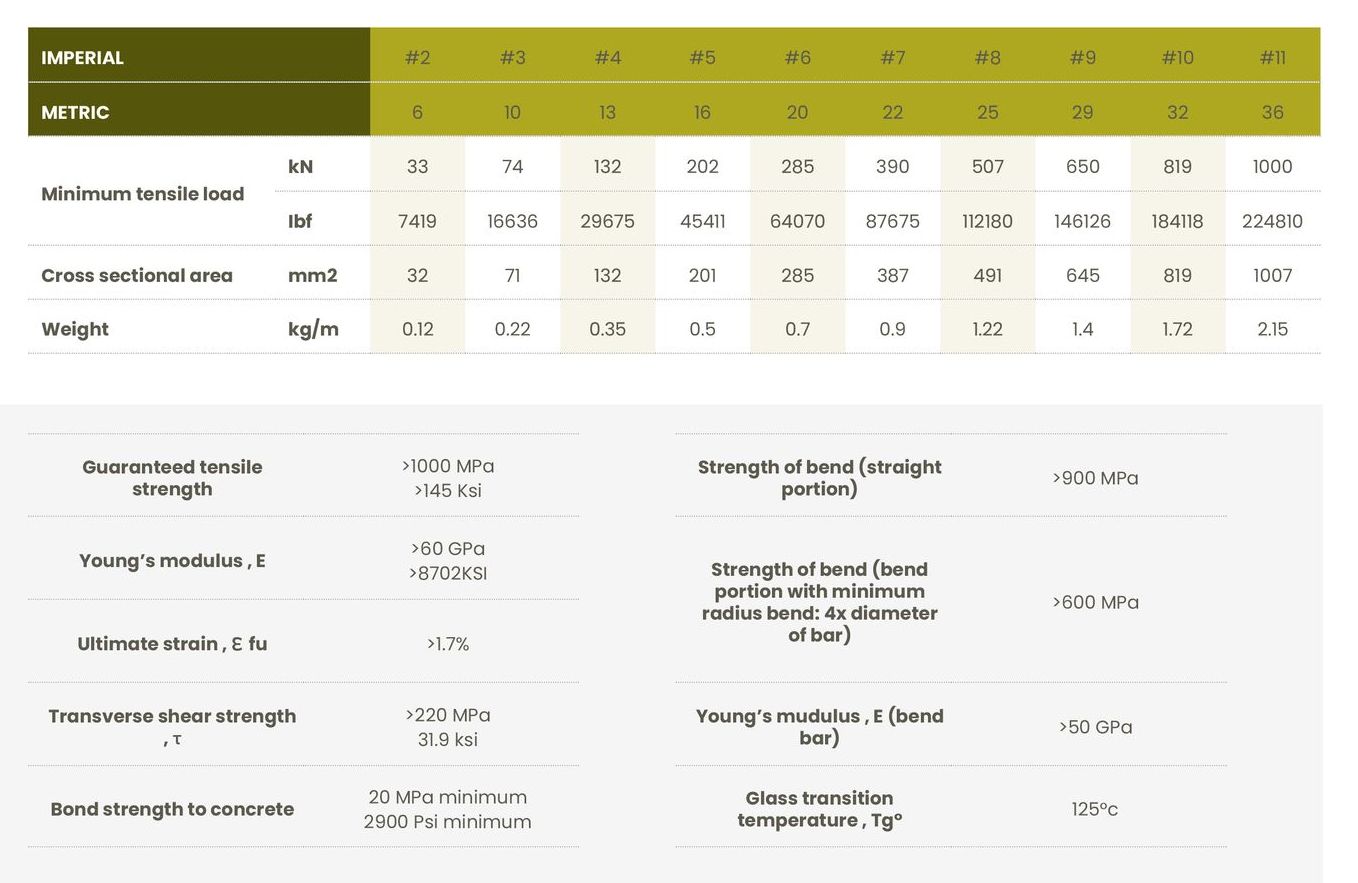

Vbar specification